SCHALLER

Schaller Visatron Oil Mist Detection Systems

The VISATRON® devices use infrared turbidity measurement for continuous oil mist detection, featuring durable, interchangeable components and built-in protection against contamination and condensation.

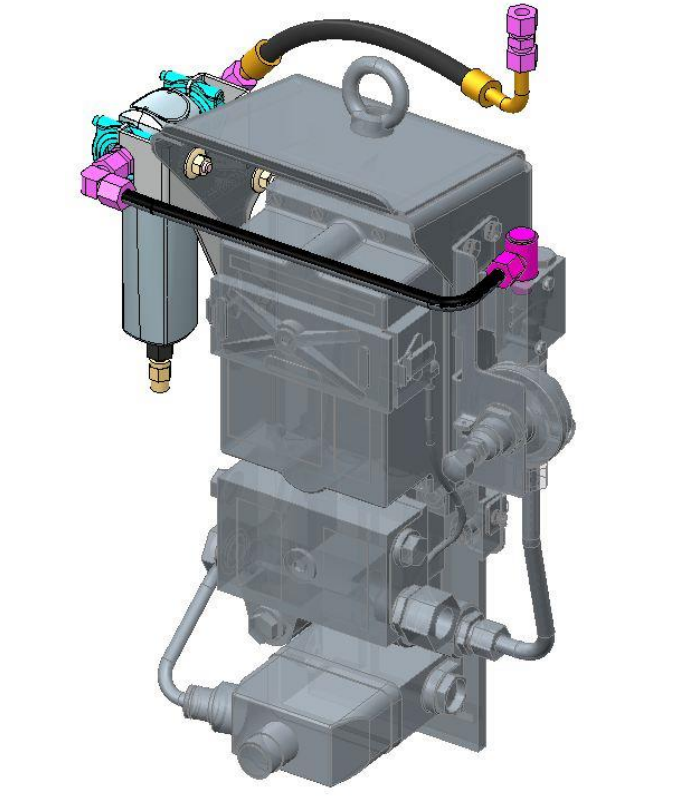

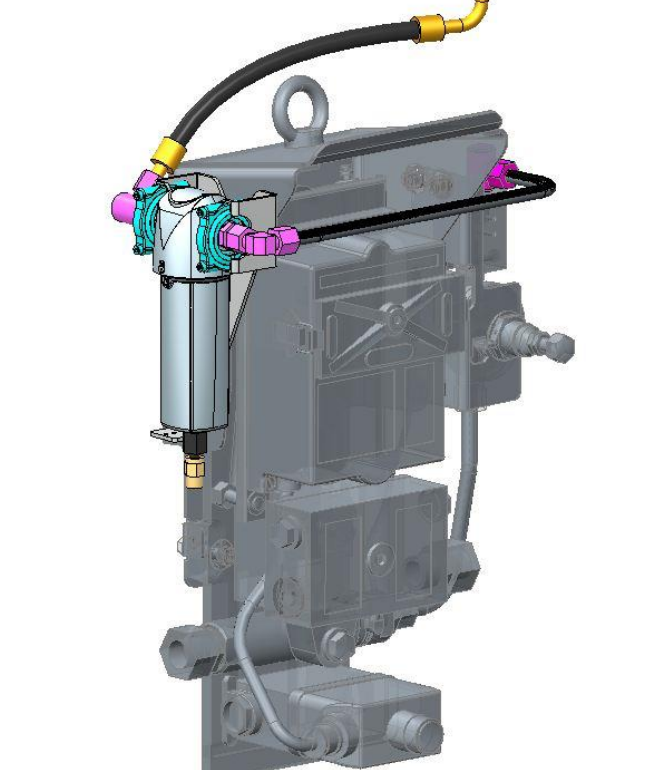

Oil Mist Detectors play a crucial role in protecting large Diesel, Gas, and Dual Fuel engines from severe damage caused by oil mist explosions, which can result from the overheating of bearings or other moving parts. Schaller VISATRON® Oil Mist Detection Systems provide continuous monitoring of the crankcase atmosphere in every engine compartment through a suction system. The necessary suction is generated by a wear-free air jet pump powered by compressed air. This technology, proven and widely accepted by both engine manufacturers and ship owners, offers high operational reliability and significantly lower maintenance costs compared to other systems on the market.

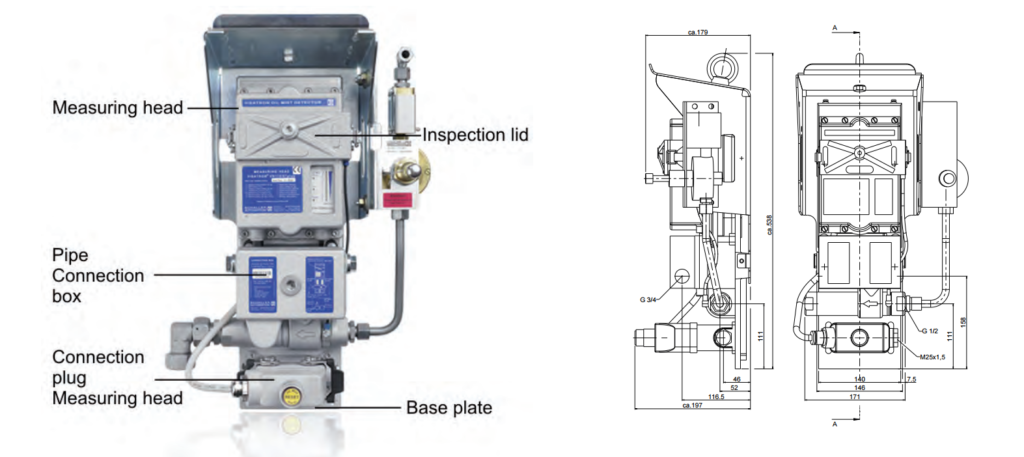

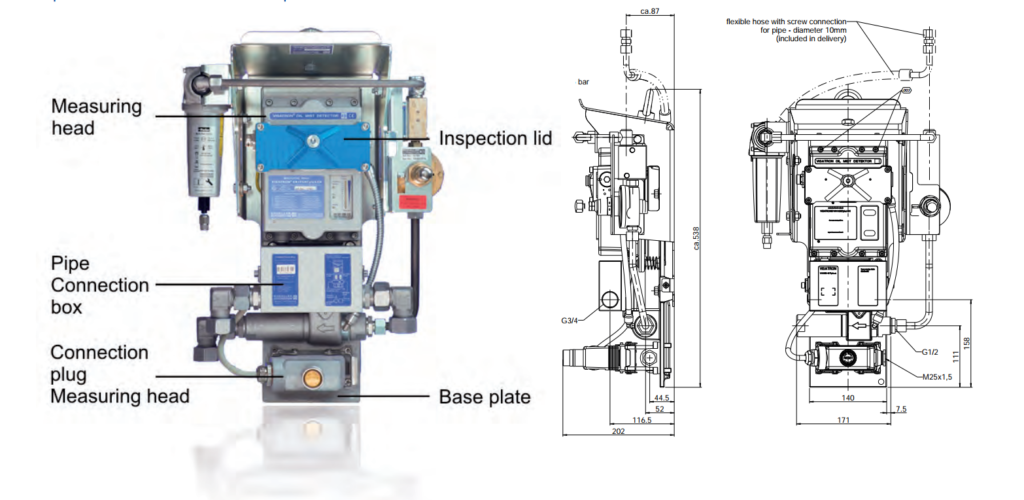

The VISATRON® series OMD-system utilizes a wear-free suction system for continuous extraction of the atmosphere from crankcase compartments and other engine locations. The system is equipped with a piping system that continuously monitors the oil mist level in the engine. Key features include:

- Piping system connected to each compartment and other engine locations.

- The VN215/93 model uses individual suction pipes for each compartment to extract its atmosphere.

- Automatic opacity adaptation for seamless operation during normal engine performance.

- Extremely low maintenance costs, designed to last for the engine’s lifetime.

- Fresh air chambers provide active dirt protection for optics.

- Built to withstand vibrations beyond standard classification rules.

- Approved by 11 classification societies for performance and safety.

- Alphanumeric display panel provides a user-friendly interface to view and adjust parameters.a

VISATRON® series OMD-systems

Key Features

- Relay Outputs: Equipped with three relay outputs for system readiness, pre-alarm, and high oil mist alarm (main alarm).

- Continuous Monitoring: Continuously samples the atmosphere from each crankcase compartment via a suction system, with a wear-free air jet pump generating the required vacuum using compressed air.

- Optical Measurement: Measures turbidity of the sample flow by infrared light absorption, with % Opacity used as the unit of turbidity (100% Opacity = total light absorption; 0% Opacity = no absorption).

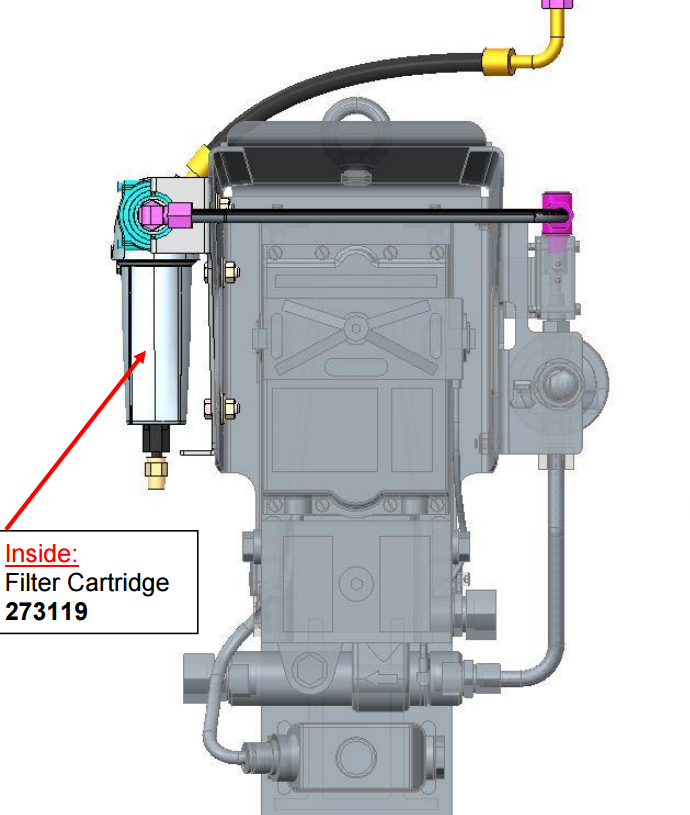

- Scavenging Air Chambers: Supplied with fresh pressurized air instead of engine atmosphere, protecting the optical system from dirt contamination and keeping filters clean for longer.

- Condensation Prevention: A heating unit in the measuring head prevents condensation, reducing the risk of false alarms due to humidity around the optical system.

- Remote Monitoring Capability: Features an RS 485 interface for connection to a remote monitoring unit, with an alternative 4-20 mA connection option.

- Pre-Alarm Functionality: Activates a separate pre-alarm relay at 70% opacity of the main alarm level, providing an early warning before engine shutdown due to high oil mist concentration.

How Visatron Oil Mist Detection Systems Works

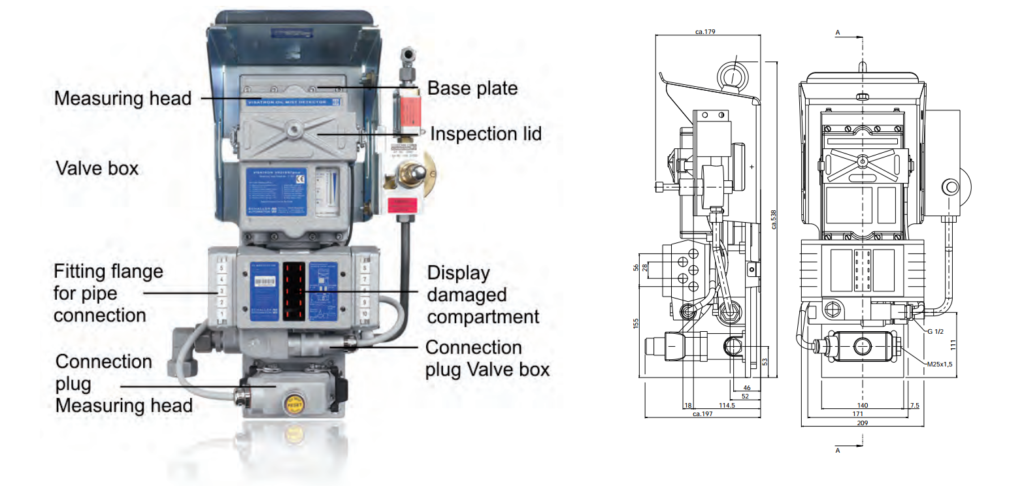

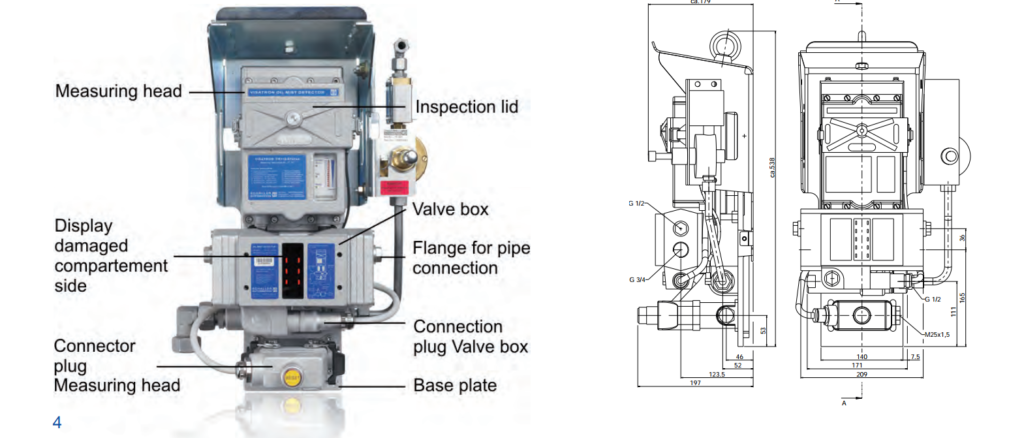

Damage detection is carried out through a header pipe sampling system that monitors the atmosphere within the crankcase compartments. When overheating occurs in one of the compartments, the system identifies the specific half of the crankcase where the damage has occurred.

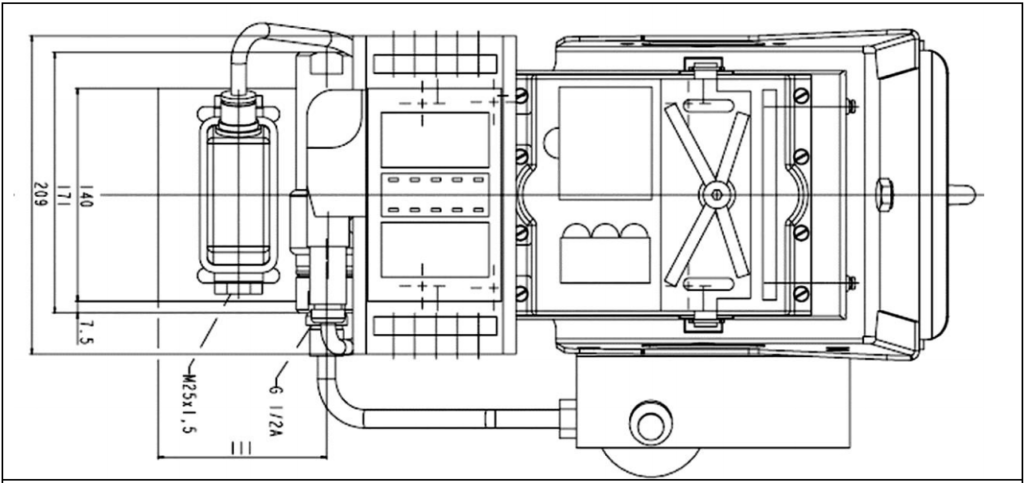

- Sampling Process: The atmosphere from each crankcase compartment is collected and passed through a header pipe into the valve box. From there, it flows into the opacity measurement path within the measuring head’s housing.

- Opacity Measurement: If the opacity of the atmosphere mixture exceeds 10% of the pre-set alarm threshold, a “damage check” is initiated.

- Damage Localization: During the damage check, the system switches the valves in the valve box according to a specific algorithm to pinpoint which half of the crankcase contains the overheating issue.

- Alarm Sensitivity: The alarm threshold is adjustable to four levels. Compared to the VN115/87plus, this system offers increased sensitivity by triggering an alarm if the difference in opacity between the two halves of the crankcase exceeds 20% of the set alarm threshold.