Tanktech Korea Portable Tank Measuring System

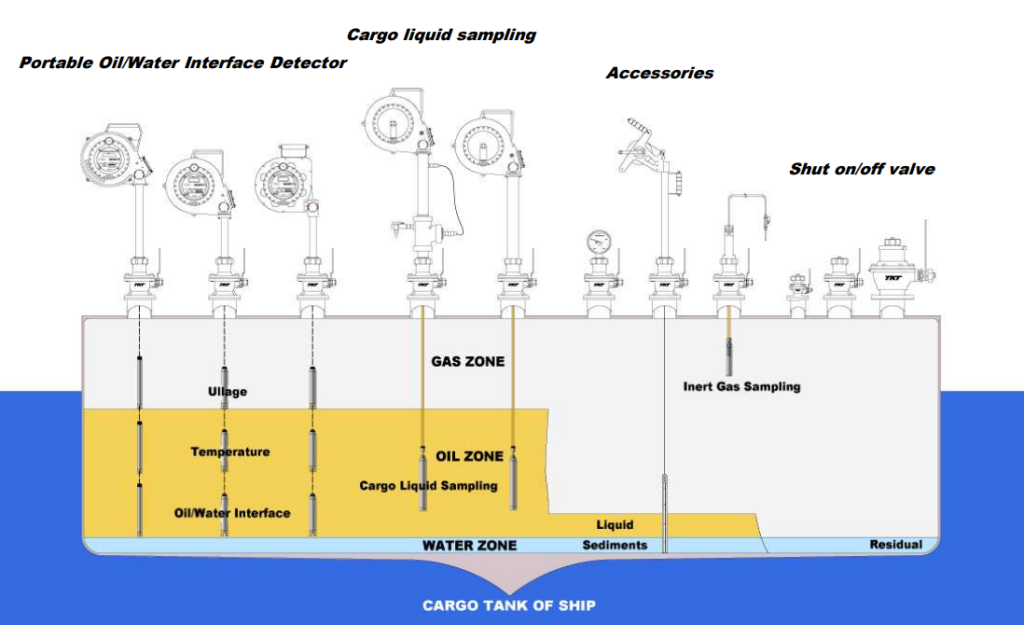

A Portable Tank Measuring System (PMS) is a device used to monitor and measure the contents of tanks on tankers, specifically designed to ensure safety and accuracy in the determination of oil/water levels within the tanks. This system complies with various International Maritime Organization (IMO) regulations for preventing contamination and ensuring safe discharge operations.

Semi-Closed (Restricted) Type

- Penetrates the tank.

- Allows a small quantity of cargo vapor or liquid to be exposed to the atmosphere when in use.

- Fully closes when not in use to prevent dangerous escapes of tank contents.

- Example MODEL T2000-TFS-01

Closed (Gas-Tight) Type

- Penetrates the tank but is part of a closed system, preventing the release of contents.

- Can use float-type systems, electronic probes, magnetic probes, or protected sight glasses for measurement.

- Alternatively, indirect devices like weighing systems or pipe flow meters can be used without penetrating the tank.

- Example MODEL T2000-TFC-01/02

Regulatory Compliance

- IMO Regulation 15 (3)(b): Requires effective oil/water interface detectors for accurate measurement and rapid determination in slop tanks and other relevant tanks.

- IMO Resolution MEPC.5(XIII): Ensures that instruments are capable of determining the oil/water interface in tanks from which effluents are discharged directly into the sea.

- IMO Resolution A.446(XI): Stipulates that level gauges or hand-dipping arrangements must be in place to check for dryness of cargo tank bottoms, ensuring no oil accumulation.

Benifits

- Provides accurate and efficient monitoring of tank contents.

- Ensures safety during operations by preventing dangerous escapes of cargo.

- Complies with international regulations for safe handling and discharge of oil and water.

All kinds of TANKTECH Portable Measuring System >>

Types of TANKTECH Portable Measuring System

The Oil/Water Interface Detector ensures efficient detection of the oil/water interface in slop and other tanks. Approved by the Administration, it enables safe effluent discharge, complying with IMO Resolution MEPC. 5 (XIII) for preventing marine pollution with high accuracy.

The Cargo Liquid Sampling Device is designed for the safe and efficient collection of oil samples from storage tanks. This device allows for precise sampling without leakage or gas emissions, making it ideal for oil tank operations.

The Tank Bottom Liquid & Sediment Checking Device is designed for accurately verifying the dryness of the cargo tank bottom after cleaning, ensuring compliance with International Maritime Organization (IMO) regulations for tanker safety and pollution prevention.

The Inert Gas Sampling Hose & Adaptor is designed for measuring oxygen levels in cargo tanks by connecting a portable oxygen tester to the gas sampling device on the deck. This connection ensures a secure, leak-free operation during gas sampling, making it ideal for maintaining safety in tanker operations.

The Pressure Gauge is a portable device designed for monitoring pressure in tanks by connecting directly to the TANKTECH shut on/off valve. It offers precise pressure readings, making it a reliable tool for managing tank operations.

The Vapor Control Valve, also known as the Shut On/Off Valve, is a device used to ensure safe and effective testing of cargo tanks after cleaning. It allows for the monitoring of the tank bottom’s dryness, while preventing the release of dangerous gases during tank gauging.